Pipe cutting , pipe bevelling & flange facing machine qatar

Pipe Cutting Machines - Qatar

A pipe cutting machine is a specialized tool designed to precisely and efficiently cut pipes of various materials such as metal, plastic, and concrete, making it indispensable in industries like plumbing, construction, manufacturing, and oil and gas; these machines range from manual and electric cutters to advanced hydraulic, orbital, and laser cutters, each offering specific features such as high precision, speed, versatility, and safety, thereby significantly enhancing productivity and ensuring high-quality results in applications requiring accurate and clean pipe cuts.

Pipeline and Pipe Bevelers - Qatar

Pipes and pipelines must undergo beveling and machining to achieve a proper fit and weld. This process utilizes a pipe cutting machine Qatar alongside a pipe beveling machine to create a beveled edge on the pipe end, ensuring precise alignment and strong welding joints. Skilled professionals perform this task using advanced equipment like split-frame clamshells, internally mounted pipe bevelers, and other high-quality pipe cutting solutions. Additionally, we offer a wide range of accessories to guarantee the safe and efficient operation of pipelines. Whether you need a pipe beveling or pipe cutting machine in Qatar, our solutions are tailored to meet your requirements.

SFSF

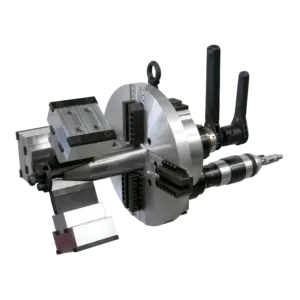

Split Frame, Clamshell Beveling Machines

Highly powerful, large professional tool, designed specifically for pipeline industry. Thanks to slim body – easy to handle.

RANGE: 60.32 –

1219.2 mm

MINILATHE

Machine for Beveling Tubes, With Gears

Powerful machine with powerful 2.2kW (3 HP) motor, gearbox and innovative locking system. One mandrel covers entire tool range.

RANGE: 72 –

406 mm

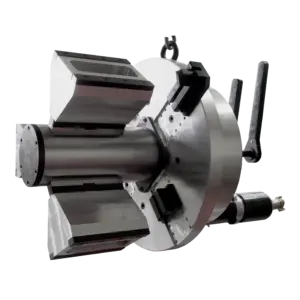

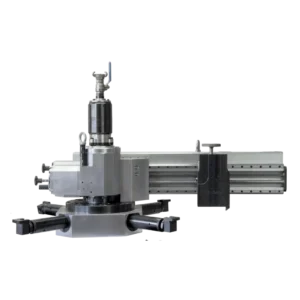

PIPELATHE

Pipe Facing and Beveling Machine

Machine with 3.5 HP pneumatic drive. Variable speed control. Innovative locking system. One mandrel covers entire tool range.

RANGE:

180 –

609 mm

PIPELATHE 40

Pipe Facing and Beveling Machine, up to 40"

Large machine with 3.5 HP pneumatic drive. Speed control. Innovative locking system. One mandrel covers entire tool range.

RANGE:

180 –

1016 mm

Flange Facer - Qatar

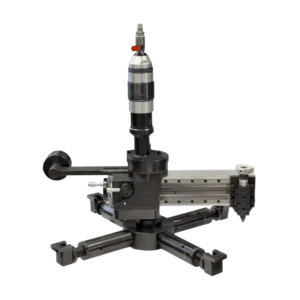

MFM

Manual Flange Facing Tool

Basic, simple and cost-effective solution for ID mount flange facing. Easy way to reface a damaged pipe flanges on site.

RANGE:

30 –

350 mm

IMFM-2430

Flange facing machine, up to 30"

Internally mounted, lightweight, super rigid yet super heavyduty machine tool. Ideal for machining all types of flange faces.

RANGE:

145 –

762 mm

IMFM-60

Flange facing machine, up to 60"

Internally mounted, lightweight and durable machine tool. Ideal for machining all types of counterbones and flange faces.

RANGE:

305 –

1525 mm

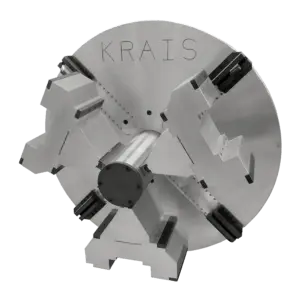

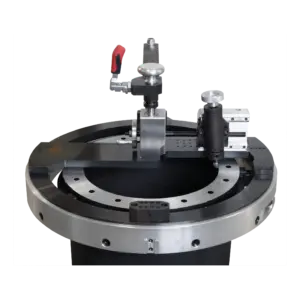

SFFM

Split frame flange facing machine

Flange facing machines mounted on the outer diameter of the flange. The feed mechanism allows for a high quality machining.

RANGE:

50 –

1200 mm