Instrumentation Tubing & Tube Fittings in Qatar

What is Instrumentation Tubing?

Instrumentation Tubing is designed for precise, leak-proof connections in fluid and gas systems. It ensures smooth, safe, and accurate transfer of liquids or gases under varying pressure and temperature conditions. Paired with tube fittings, instrumentation tubing is essential for applications that demand reliability, corrosion resistance, and easy installation.

At ABC Master Qatar, we provide high-quality instrumentation tubing and tube fittings in Qatar, engineered to meet international standards for performance and safety.

Specification List Of Tube Fittings

| Types | Tube to Female, Instrument Pipe Fittings, Tube to Union, Accessories, Tube to Male |

|---|---|

| Equivalent To | DK-LOK, PARKER, SWAGELOK, HOKE |

| Standard | ASME SA-479, Type 304-SS, BS 970 304S11, DIN 4401, ASTM A276 Type 304 |

| Sizes | 1/8’’ to 2’’ and 3mm to 50mm |

| Ends | Threaded, Welding, JIC |

| Pressure Rating | 1000 Psi, 3000 Psi, 6000 Psi, 10000 Psi |

| Threads | NPT , BSPT, BSPP |

| Specification | Items Made from Hex – ASTM A276; Items made from Round Bar- ASTM A182 |

| HS CODE | 73072900 |

How Do Instrumentation Tube Fittings Work?

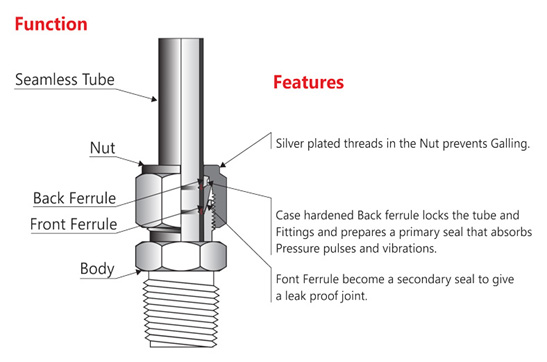

Instrumentation tube fittings are designed to create a strong, leak-proof connection between a tube and another component such as a valve, manifold, or equipment port. Here’s how they work:

- Insertion – The tube is inserted into the fitting body until it bottoms out.

- Tightening – When the nut is tightened, it pushes the ferrule(s) forward.

-

Compression – The ferrule(s) grip and compress the tube surface, forming a tight mechanical seal.

- Sealing – This compression ensures no leakage, even under high pressure, vibration, or thermal expansion.

- Single Ferrule Fittings compress with one ferrule to form the seal.

- Double Ferrule Fittings use two ferrules—one for sealing and the other for holding strength.

Types of Instrumentation Tube Fittings

- Compression Fittings : Consist of a nut, front ferrule, and back ferrule. When tightened, the ferrules compress around the tubing, creating a strong, leak-proof seal. These fittings are easy to install and resist vibration.

- Double Ferrule Fittings : Also known as twin ferrule fittings, they feature two ferrules. The front ferrule ensures sealing, while the back ferrule adds strength and prevents leakage. Ideal for high-pressure and high-vibration systems.

- Single Ferrule Fittings : Simpler in design, with a single ferrule compressed against the fitting body to form a reliable seal. A practical choice for moderate applications where ease of installation is a priority.

- Adapter Fittings : Used to connect tubing to threaded or weld fittings. Options include:

- Weld Fittings: Pipe Socket Weld, Tube Socket Weld, Butt Weld

- Threaded Fittings: ISO/BSP, NPT, SAE

- Flare Fittings: JIC and AN Fittings

- Special Purpose Fittings: Calibration, dielectric, bore-thru, orifice, and custom fittings

Applications of Instrumentation Tube and Fittings

- Oil & Gas Industry – For upstream, midstream, and downstream operations, connecting tubing in hydraulic systems, control panels, and instrumentation units.

- Chemical Processing – Ensures leak-proof connections in injection systems, analyzers, and process monitoring equipment.

- Pharmaceuticals – Provides clean, hygienic, and precise tubing connections for chromatography systems, reactors, and bioprocessing units.

- Petrochemicals – Used in refining, production, and pipeline monitoring to maintain reliable flow and safety.

- Power Generation & Industrial Plants – Supports steam, water, and process fluid control with dependable tube and fitting systems.

Common Features of Instrumentation Tubing & Tube Fittings

We also manufacture and supply custom size compression fittings in Qatar for specialized applications. These fittings are built to exact requirements and are available in a wide range of configurations.

- Adapter Fittings – Transition tubing to welded or threaded ends.

- Weld Options – Pipe Socket Weld, Tube Socket Weld, and Butt Weld.

- Threaded Options – ISO/BSP, NPT, SAE, OSM, OSC standards.

- Flare Fittings – JIC and AN fittings for hydraulic and pressure systems.

- Special Purpose Fittings – Custom solutions such as calibration, dielectric, special orifice, bore-thru, and engineered designs.

- Shapes & Styles – Adapters, male & female connectors, unions, reducers, tees, elbows, caps, crosses, plugs, and bulkhead fittings.