Needle Valve

What is a Needle Valve?

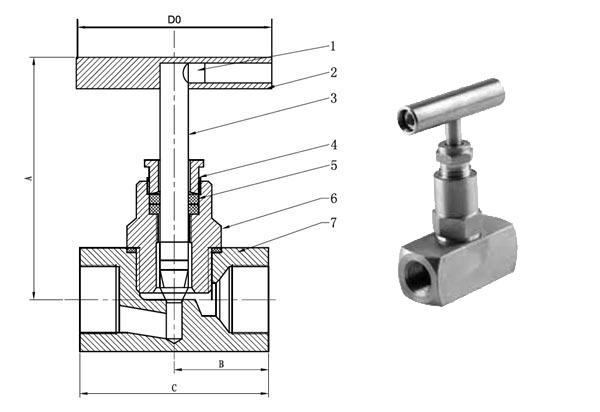

A needle valve is a precision flow control device used to regulate the flow of liquids or gases in a system. It features a slender, needle-shaped plunger that fits into a conical seat. By turning the valve stem, the operator can gradually increase or decrease flow, allowing for fine control that other valves cannot provide.

At ABC Master Qatar, we supply durable and reliable needle valves in Qatar designed to withstand high pressure, temperature variations, and demanding industrial environments.

Specification format of Hydraulic Needle Valve

| BRAND NAME | TU-LOK |

| VALVE SIZE | 1/8" TO 2" / 6 MM TO 50 MM |

| THREAD | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| CONNECTION | THREADED, TUBE END, BUTT WELD, SOCKET WELD, FLANGE END |

| FLOW PATTERN | STRAIGHT, ANGLE, CROSS PATTERNS |

| FUNCTION | 2 WAY, 3 WAY |

| BODY SHAPE | SQUARE, ROUND, HEXAGON |

| PRESSURE RATING | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI, 15,000 PSI, 20000 PSI |

| ORIFICE SIZE | 2 MM TO 9.5 MM |

| MEDIA | HYDRAULIC OIL, AIR, WATER, GAS, STEAM, HOT WATER, COLD WATER, SEA WATER, CHEMICAL |

| MEDIA TEMPERATURE | (-120°C TO 500°C) RANGE AS PER PRESSURE |

| BODY TYPE | BAR STOCK, FORGED |

| HANDLE | BAR T-HANDLE, KNOB HANDLE, WHEEL HANDLE |

| PACKING DETAILS | BOX PACKING, WOODEN PALLET |

| EQUIVALENT BRANDS | SWAGELOK, PARKER, DK-LOK, HAMLET, OLIVER VALVES, HOKE |

| MATERIAL | SS 304, SS 316, SS 316 TI, BRASS, COPPER, CS, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, ALLOY 20, TITANIUM, 904L & ALL OTHER ALLOYS |

| APPLICATION | SUGAR, OIL & GAS, TEXTILE, POWER, WATER & WASTE WATER TREATEMENT, CHEMICAL PROCESS INDUSTRIES |

Types of Needle Valves We Supply

At ABC Master Qatar, we offer a complete range of needle valves in Qatar, available in different materials, sizes, and connection ends.

- Screwed End Needle Valve – Simple threaded connection for easy installation.

- Tube End Needle Valve – Designed for leak-free connection to tubing.

- Socket Weld Needle Valve – Provides high-strength weld connections for critical systems.

- Butt Weld Needle Valve – Ensures permanent, leak-tight welded joints for high-pressure pipelines.

- Angle Needle Valve – Allows 90° turn for flow direction changes in compact spaces.

- Hexagonal Needle Valve – Compact body with hex design for ease of installation.

- 3-Way Needle Valve – Offers multi-directional flow control in complex systems.

- Union Bonnet Needle Valve – Provides reliable sealing and easy maintenance.

- Panel Mounted Needle Valve – Designed for instrument panels and system integration.

- Forged Needle Valve – High-strength forged body for durability under extreme conditions.

- Knob Handle Needle Valve – User-friendly operation with quick adjustment.

- Globe Handle Needle Valve – Traditional handle for controlled flow adjustment.

- Wheel Handle Needle Valve – Large handle for precision control in fine adjustments.

- Flange End Needle Valve – For robust, high-pressure flange connections.

- Needle Valve with Vent – Equipped with vent ports for pressure release and system safety.

How Do Needle Valves Work?

The operation of a needle valve is simple yet highly effective.

- Opening – When the valve stem is rotated counter-clockwise, the needle moves away from the seat, creating a small passage for fluid to flow.

- Flow Regulation – Because of the tapered needle design, the operator can precisely adjust the amount of flow by making small turns.

- Closing – Turning the valve stem clockwise moves the needle back into the seat, completely shutting off the flow.

This design makes needle valves ideal for applications requiring accurate flow control and leak-tight shutoff.

Applications of Needle Valves

- Oil & Gas Industry – In the oil and gas sector, needle valves in Qatar are essential for pressure control, process regulation, and instrumentation systems. They are used in wellhead assemblies, sampling lines, and control panels where precision and leak-proof operation are critical.

- Chemical & Petrochemical Plants – Needle valves are vital for handling aggressive chemicals and corrosive fluids in injection systems, monitoring equipment, and sampling lines. Their corrosion resistance ensures safety and reliability in refining and petrochemical processes.

- Power Generation – Power plants depend on needle valves in steam lines, condensate systems, turbines, and boilers. Built to withstand high pressure and temperature, they provide accurate regulation that improves safety and efficiency.

- Pharmaceuticals & Food Processing- In these industries, needle valves in Qatar support hygienic and precise fluid control in bioreactors, dosing systems, and chromatography processes. They help maintain product quality while preventing contamination.

- Hydraulic & Pneumatic Systems – Hydraulic and pneumatic systems use needle valves to regulate flow in actuators, compressors, and pumps. Their fine adjustment capabilities make them perfect for metering applications and enhancing machinery performance.

Why Choose ABC Master Qatar for Needle Valves?

- Wide range of needle valves in Qatar for every industry

- Manufactured to international standards for quality and safety

- Durable designs available in stainless steel, brass, carbon steel, and special alloys

- Local stock and fast delivery across Qatar

- Technical support and expert guidance for valve selection